Automated Cold Storage is one of the hot topics in the food and drink sector as companies look to improve efficiency and reduce costs in their cold store warehouses.

The increase in energy and running costs is presenting operators and food companies with complex challenges which may be restricting growth, profitability, and service.

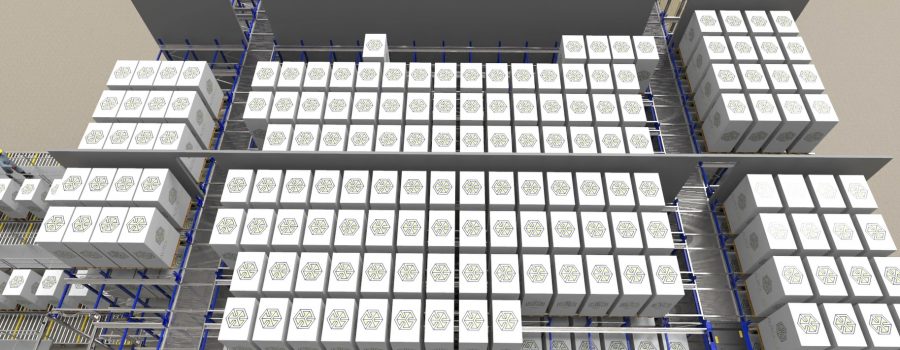

To remain competitive, cold store operators are now looking at new opportunities presented by automated racking systems for cold storage, such as Thistle Systems’ AUTOCUBE™, as they attempt to find a solution which can provide them with a tangible competitive advantage and highly attractive return on investment.

How Does Automated Cold Storage System Work?

The automated cold storage approach does away with the need for operators and forklift trucks to enter the cold store and therefore the need to have large aisles within the cold store.

By using a combination of 6-directional smart carriers, lifts and transport rails, pallets can be automatically stored and retrieved from the racking system at the touch of a button – or to a pre-programmed picking list.

The automated racking solution is controlled by intelligent software system which manages the entire process, understands where pallets are in the system and can position them intelligently so that fast moving items are stored closer to the entrance/picking zones to minimise travel times and improve efficiency.

So, What Benefits Can Automated Cold Storage Deliver?

Automated Cold Storage Warehouse can provide the following core benefits:

1. Increased Capacity/Reduced Footprint of Cold Stores

By reducing the aisles required for forklift trucks and operators, you can dramatically increase the number of pallet positions in your cold store OR alternatively, if you are looking to build a new cold storage unit, you could achieve the same storage capacity in an area which is dramatically less than a traditional storage solution.

2. Dramatically Reduce Cold Storage Warehouse Costs

The operating costs in any warehouse are one of the biggest overheads, however with the additional energy costs involved in running a cold store warehouse, the operating costs are significantly more.

However, automating your warehouse enables you to dramatically reduce your operating costs in a number of ways.

Like other automated warehouse systems, the ability of the system to automatically store and retrieve pallets to and from the cold store, with minimum manual intervention reduces the requirements for forklifts and operators and the massive costs they bring – for more details, read our white paper on “Eliminating Costs in Your Warehouse through Automation.”

However, Automated Cold Stores also enables you to achieve significant energy savings, especially when you look at things on a cost per pallet stored.

The ultra-high-density nature of the Automated Storage System reduces the amount of air to be chilled in the cold store and therefore the climate control costs.

The automated system also enables you to dramatically reduce the size of doorways and therefore the ingress of the hotter outside air – again reducing chilling costs.

And doorways can be designed to be open less, particularly if you use doors which automatically open and close when pallets are passing through – again reducing energy costs.

3. Faster Product Picking in Cold Stores

By preventing the need for forklifts and operators to enter the system, Automated cold storage solutions, such as AUTOCUBE™, can dramatically improve picking times, especially when multiple carriers are used.

Picking orders can be pre-programmed to bring pallets closer to the picking/loading area during downtimes or overnight, ready for rapid access.

With an inbuilt learning system, AUTOCUBE™, will build a profile of stock movements and gradually move fast moving pallets and items closer to the picking area to continuously improve the picking process.

4. Creating Safer Working Environment

Any environments that require manual labour and moving equipment, such as forklift trucks, to operate in the same space will present a risk of injury and damage. The more equipment and operators in the space, the more likely an incident will occur.

By removing the need for forklift trucks and operators to enter the cold store, automated systems eliminate the risk of manual accidents. With all operations controlled remotely by a dedicated software system, carriers and lifts work in perfect harmony to avoid collisions, blockages, and bottlenecks.

5. Improved Inventory Control

Inventory control and stock shrinkage is an issue for most warehouses and can happen for several reasons including theft and damage to stock.

By limiting access to the stored products, monitoring all pallet movements, and creating a dedicated zone to pick and load from the store, systems such as AUTOCUBE™ Automated Racking Solution will dramatically reduce the opportunity for operators to steal products.

And as all stock movements are controlled by carriers on dedicated transport rails as opposed to manually operated forklift, there is less risk of damage to the goods being stored and the racking structure itself.

Conclusions

Automated Racking Solutions, such as Thistle Systems’ AUTOCUBE™, can provide cold store operators with significant benefits and a highly attractive Return on Investment. By increasing capacity in the same footprint, improve accessibility, increase efficiency as well as dramatically reducing the operating costs, operators can create a real competitive advantage which is increasingly critical in today’s marketplace.