In the rapidly evolving world of warehouse automation, precision matters. Getting it wrong can mean operational disruption, costly downtime, or failure to meet fulfilment targets.

That’s why simulation has become a cornerstone of modern automated warehouse solutions—and nowhere is this more evident than with Brightpick.

The Power of Simulating Before Investing and Deploying

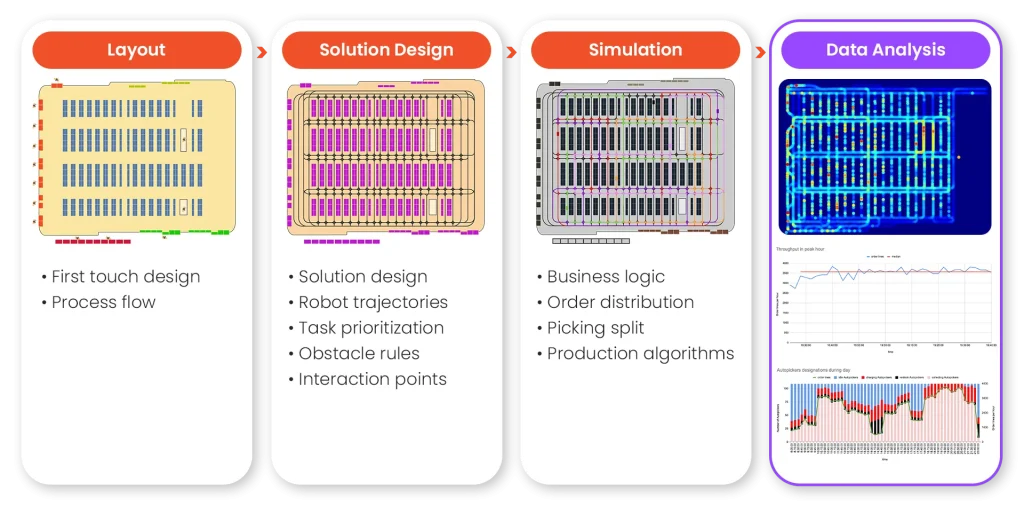

At Brightpick, every installation is rigorously simulated before a single robot touches the floor. This isn’t a theoretical exercise—it’s a data-driven, high-fidelity model that mirrors real-world performance thanks to the same Brightpick Intuition software that powers the live robotic fleet.

By simulating the entire operation early in the design process, Brightpick can accurately predict:

- Peak and average throughput

- Robot utilisation rates

- Order fulfilment times

- Labour requirements by hour

- Traffic heatmaps and risk zones

These simulations aren’t just generic or based on assumptions. They’re powered by real operational data—both from the customer’s current site and from Brightpick’s deployed fleet across other facilities. That allows for a level of predictive accuracy that’s virtually impossible to achieve with spreadsheets or manual planning.

What You Get From a Brightpick Simulation

Each Brightpick simulation delivers far more than just estimates—it provides concrete, actionable insights that de-risk your automation journey:

A multi-hour 2D simulation of robots operating in your digital warehouse, reflecting your real order profiles, layout, and logic.

Detailed performance report covering:

- Order throughput during both average and peak periods

- Robot utilisation, charging cycles, and idle time

- Time to fulfil each order

- Labour demand by the hour

- Heatmaps visualising robot traffic across aisles, picking zones, and restocking areas

- Evidence showing how the system meets your space constraints, throughput goals, and labour reduction targets

Reliable, verifiable metrics that give you the confidence to proceed with full implementation—knowing exactly how Brightpick will perform.

The Benefits Go Beyond Insight

Brightpick’s simulation isn’t just a planning tool—it’s a strategic asset.

- Validate scalability before deployment and model the impact of adding extra robots or enabling features like lights-out overnight picking.

- Test multiple layouts or workflow logics to optimise your warehouse footprint and performance.

- Preview system behaviour using your real production rules and order structure.

- Avoid surprises—identify potential risks and bottlenecks before they become live issues.

In short, it’s the most effective way to ensure your automation project hits the ground running.

Why Warehouse Simulation Matters

Simulation gives clients considering Warehouse Automation something invaluable: confidence.

- Smarter Design Decisions: Test different layouts, pick strategies, or throughput targets without disrupting live operations.

- Confident Planning: Understand how your system will perform at peak demand before it goes live.

- Reduced Risk: Identify congestion zones, resource bottlenecks, or under-utilised assets before they become real-world issues.

In short, simulation makes it possible to de-risk automation investments and fine-tune them for maximum performance from day one, with the same intelligence that drives the actual system.

The Future of Your Warehouse Simulated

In a market where agility, scalability, and ROI are critical, simulation isn’t a luxury—it’s essential.

And for customers working with Thistle Systems—the exclusive UK partner for Brightpick—it means you can move forward with automation projects backed by clarity, precision, and proven performance.

Contact us today to find out how you could transform the efficiency of your warehouse operations.

Call 01236 453888 | Enquire now

Looking to Automate Pallet Storage?

If automation is right for you, however your requirements differ from Brightpick’s offerings, explore our options: AutoCube. – Automated Pallet Storage Solution. A solution that transforms capacity, efficiency and operating costs providing a revolutionary approach to warehouse design.