The demands being placed on distribution centres are at an all-time high as customers demand even shorter lead times, with many companies being forced to offer next day or even same day delivery service just to compete.

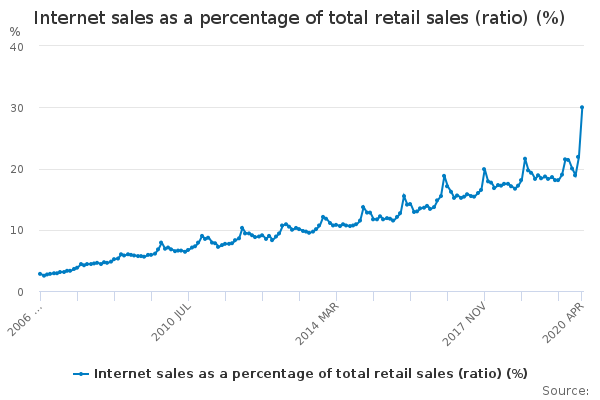

Much of this is being driven by the continued growth in internet sales which reached an all-time high in April 2020 where it accounted for 30% of all retail sales in the UK according to the Office of National Statistics.

And whilst the large spike in internet sales can be attributed to the Coronavirus pandemic, the signs are very clear to see that there is no stopping this trend and warehouses and distributions centres must prepare for change.

This is making Distribution Centres look at new ways to dramatically improve efficiencies by storing more products in the minimum space and with an order fulfilment system capable of reducing pick times and minimising errors.

These demands, combined with increasing labour costs due to the continual rise of the National Minimum Wage, have seen a dramatic growth in semi-automated Goods to Person Storage Systems, including:

However as demands continue to grow on systems to improve order fulfilment, goods to person systems have developed to offer increasingly sophisticated automated systems including:

- Automated pallet storage

- Vertical carousels

- Automated bin-type storage solutions.

These powerful systems are revolutionising warehouses and distribution centres with a step change to efficiencies, capacity and operating costs.

The optimum application for each of these automated goods to person storage solutions will be dependent on the goods being stored, the number of SKUs, the pick quantities and the required pick rates.

Key Benefits Of Automated Goods To Person Storage

These automated goods to person storage solutions offer a number of key benefits including

- Space – offering ultra-high density storage to reduce the total storage footprint required

- Productivity – By bringing the products to the person, you are eliminating travel times, whether walking or forklifts, increasing throughput, increasing picks per cycle and reducing errors

- Security – products are stored out of reach of the operators and only presented at the request of the software.

- Scalability – both systems are modular and can grow with companies storage and picking requirements

Automated Goods to Person storage solutions offer a highly efficient combination of capacity and throughput and can suit a wide range of sectors and applications in distribution centres.

To see which Good to Person Storage solution is right for your company, contact us now on 01236 453888.

Goods to Person Storage Systems | Automated Distribution Centres