Drive-in racking is a firm favourite when it comes to high-density racking solutions, especially in distribution centres and cold stores where maximising capacity is a key driver.

However, like every industrial racking system, drive-in pallet racking isn’t perfect and doesn’t suit every project.

So whilst drive-in racking may appear to be a cheaper investment, the true cost of drive in racking and the impact it has on capacity, utilisation and most importantly ongoing operational costs, can have a dramatic impact on the overall efficiency of your warehouse.

That is why we are seeing a growing number of clients who are looking to convert their existing drive-in racking solution to radio shuttle racking.

So, what is the difference between drive-in racking and radio shuttle racking?

Below we look at the 5 major reasons why companies are switching to radio shuttle racking and explain the massive return on investment that they are enjoying.

5 Reasons Why Clients are Moving from Drive-In Racking to Radio Shuttles

- Increase in storage capacity

Drive-in racking is seen as a superb high-density storage solution however, it has its limitations.

As the name suggests, drive-in racking requires a forklift truck to enter the system to deliver and retrieve pallets. If you try to make the system too deep or too high, the time and effort to carefully position the pallet makes it virtually impractical to operate effectively.

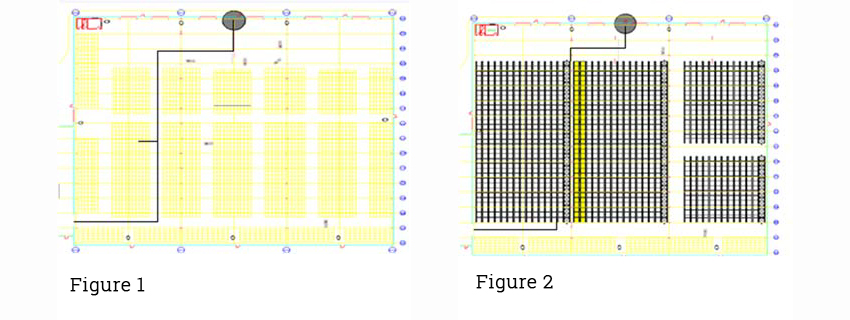

The traditional approach is to restrict the drive-in racking to approximately 4 pallets high and 7‐10 pallets deep which tends to see a grid layout with operating aisles for forklift trucks – see figure 1.

With a Radio Shuttle System, the forklift never enters the system. The radio shuttle does all of the work to take the pallet from the face of the system to the next available position. This enables the system to be as deep and as high as your cube allows and avoids the need for operating aisles, thus maximising the available space – see figure 2.

- Avoid Costly Racking Repairs

Manoeuvring the forklift into the racking system to deliver and retrieve pallets automatically increases the likelihood of uprights being damaged and causes the racking system to become a health and safety issue.

As a rule of thumb, we estimate that approximately 5% of uprights are likely to be damaged annually in a drive-in solution.

Replacing the damaged structure is only one element of the cost. The time and money involved in offloading the goods in the bay and the affected surrounding areas is often the biggest cost but is often overlooked in the overall cost analysis.

Compare this to the Radio Shuttle solution where the forklift never enters the racking structure, dramatically reducing the likelihood of racking damage and any ongoing maintenance to the shuttle itself can be carried out safely at ground level – often with a replacement shuttle to ensure the operations continue without disruption.

- Reduced Travelling Times

Travelling and loading times are one of the hidden costs in warehousing. Every forklift driver will be saying that they are going as fast as they possibly can and asking a forklift driver to try to speed up may only result in further damage to the racking.

But when you consider that a forklift driver may have to enter a drive-in system and carefully manoeuvre 7 pallet spaces deep before retrieving a pallet from the fourth level, you can understand why travelling times are so high.

And that doesn’t take into consideration that they may have to drive halfway across the warehouse just to access the relevant bay.

With real pressure to minimise the amount of time a wagon is sitting on the docking bay, companies have had to invest further in their fleet of forklift trucks and drivers, whereas a change in racking system may in fact offer significant long-term savings.

- Increased Utilisation

The maximum available capacity is one thing but only if you can use it.

One of the biggest issues with Drive-in Racking is managing the available pallet positions through the day to day movement of goods.

Once pallets are retrieved from the racking system, it can be difficult to replenish stocks and therefore, many companies spend significant amounts of time, for instance during the night shift, simply moving pallets within the drive-in racking to maximise their utilisation.

In the research we have carried out, we estimate drive-in racking to deliver an average of 65‐70% utilisation, however, if this utilisation rate requires significant man-hours to deliver, the hidden costs of wages and fuel for forklifts must be taken into consideration.

In comparison, a well-designed radio shuttle solution can expect to deliver on average 80‐85% utilisation.

- Energy Savings

As every company becomes more environmentally aware, coupled with government legislation and rising energy costs, more and more businesses are examining every opportunity to reduce their carbon footprint.

As well as requiring fewer forklift trucks, due to reduced travelling times, reducing electricity or LPG consumption, radio shuttle solutions also require less lighting in the middle section of the racking where there is no requirement for operators or forklifts to access.

If you would like to find out more about Maxi Cube Drive-in Racking, click here or for more information on our Maxi Cube Radio Shuttles, click here

Contact us now to discuss your project